Products

Inspection Technologies

Product Lines

Automatic vision, radiation and leak inspection systems are quickly becoming the mainstream in pharmaceutical quality control processes. The presence of particulate matter in intravenous injections presents a potentially life-threatening hazard. When it comes to inspection of small and large volume plastic or glass containers such as ampoules, vials, syringes, cartridges, bottles, and IV bags; ACIC is beyond simple pass and fail conditions. This is especially the case in the pharmaceutical or radiopharmaceutical industries where track and trace, serialization, and compliance are issues that only advanced automatic inspection and testing systems can solve.

Cameras, radiation sensors, and load cells are just part of the solution. Our deep understanding of complex issues such as multiple control stations, high-speed communication, image processing, data archiving, networking, optics, lens arrays, and extensive experience with various lighting solutions and software are fundamental to the design and build of the right solution for your quality control needs.

Our partner has extensive experience in vision algorithms including container integrity, components presence and foreign body detection, as well as a comprehensive understanding of current FDA legislation and how it applies to your process.

Artificial Intelligence Software

Our vision, leak test, and radiation inspection experience include:

- Foreign black, white, and transparent particles as well as fiber detection (particulate matter Inspection)

- Container integrity, scratches, chip, cracks, and air bubbles

- Components presence and positioning

- Filling level and meniscus control

- Headspace analysis

- Leak test

- Color identification

- Data matrix control

- Special customized application

- Alpha and gamma radiation level (see radiopharmaceutical)

Automatic Inspection Equipment

We are a leading provider of automatic inspection machines with over 40 years of expertise and knowledge in vision systems and automation. Our automatic inspection machines are equipped with proprietary artificial intelligence (AI) software that uses supervised deep learning neural network algorithms to improve detection rates while decreasing false rejections.

- Custom designed based on client inspection and facility requirements.

- Compact, flexible, and modular design that can handle multiple container formats and sizes on the same machine using change parts.

- Quick and easy changeover process.

- Containers automatically move from the infeed area to the different inspection stations in the machine. High-resolution cameras are placed at each inspection station which capture images of the containers as they pass through the station. Images are processed by the AI inspection software which determines when a defect is present in or on a container.

- Defective products are automatically removed from the line and placed in a dedicated reject bin.

- Automatic inspection machines can be integrated with upstream and downstream processes such as filling and closing machines and end-of-line packaging systems for a turnkey processing line.

- Speed: 30 – 600 pcs/minute.

- Proprietary inspection software that uses acquisition hardware (high-resolution cameras) and artificial intelligence which is based on a supervised deep learning neural network.

- We work very closely with our clients to create a custom designed and programmed inspection system that meets all requirements specific to the client’s product and process.

- We perform extensive testing in-house using the client’s exact product and typical production defect types to train the artificial intelligence system. Extensive testing and training of the AI system with real production defects greatly improves the quality of inspection.

- Improved inspection quality increases the detection rate of defects while decreasing false rejections. This saves production costs and improves patient safety.

Semi-Automatic Inspection Equipment

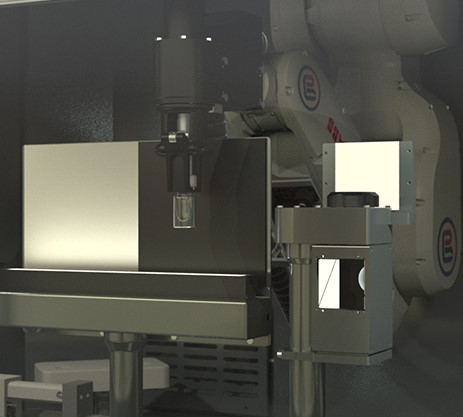

Our semi-automatic inspection machines are custom designed based on client requirements and integrate robotics and automation to complement the manual inspection processes and support operator ergonomics.

- Compact, flexible, modular design.

- Flexible robotic arms that can handle different container format types and sizes on the same machine using changeover parts.

- Robotic arm can handle containers and move them from the infeed area to the different inspection stations for manual visual inspection by operators.

- Operators will determine if containers are accepted or rejected by pressing the appropriate buttons at the operator station.

- Robotic arms will place the containers into the outfeed area if they are accepted and place them in the reject area if they are rejected.

- Stations equipped with dark and light background illuminators that are set to a defined lux value.

- Semi-automatic inspection machines can be integrated with downstream and upstream processes.

- Adjustable height for operator ergonomics.

- Emergency buttons and interlocks for maximum operator safety.

- Touchscreen monitor.

- Speed: 30 – 600 pcs/minute.

- Vials

- Syringes

- Bags

- Cartridges

- Bottles

- Custom container types

Manual InspECTION EQUIPMENT

Ergonomic, compact manual inspection stations for visual inspection of pharmaceutical containers (vials, bags, syringes, bottles, cartridges) by human operators.

Manual inspection stations are custom designed based on customer processes and facility requirements.

- Stations equipped with dark and light background illuminators that are set to a defined lux value

- Adjustable height for operator ergonomics

- Manual inspection stations can be integrated with downstream and upstream processes

- Compact, flexible, modular design

- Layout is custom designed based on customer requirements

- Emergency buttons and interlocks for maximum operator safety

- Vials

- Syringes

- Bags

- Cartridges

- Bottles

- Custom container types