Products

Bag Forming

We provide automatic lines for the manufacturing of medical bags including IV bags, blood bags, ostomy, drainage, and urine bags.

Product Lines

Blood Bags

UNIBLOOD Model

- Product: Medical blood bags from 300 ml to 500 ml with 2, 3, 4, or 5 tubes

- Output: 1440 pieces/hour

- Maximum reel diameter: 400 mm

- Maximum reel width: 270 mm

- Maximum film incision press closing force: 300 kg

- Press electrode-holder plate dimension: 300×600 mm

- Press working plate dimension: 600×600 mm

- Maximum indexing unit forward: 550 mm

- Film incision output power of the generator: 8 kW

- Tube output power of the generator: 12 kW

- Perimeter output power of the generator: 12 kW

- Working frequency: 27.12 MHz ± 0.6%

- Feeding voltage: 400 V – 3Ph+G – 50 Hz (other voltages on request)

- Compressed air pressure: 0.6 Mpa

- 2-position reel-holder with unwinder

- High frequency welding press pneumatically operated for film incision

- High frequency generator incorporated in the structure of the press

- Cutting unit for upper side of the bags

- Film index unit with multiple clamps

- Selection and loading unit for tubes

- High frequency welding press pneumatically operated for tubes

- High frequency welding press pneumatically operated for bag perimeter

- Bag labelling unit

- Bag cutting station and scraps separation

- Bag lifting and dispatch to the filling machine

- Liquid circulation refrigeration unit

- Control panel with PLC (remote service on request)

- Push-button panel with touch screen

Blood Filters

GMA-D + PDT Model

- Product: EVA medical bags for enteral alimentation, 2000 ml

- Output: custom

- Maximum welding press closing force (adjustable): 2500 kg

- Welding press electrode-holder plate dimension: 700×800 mm

- Welding press working plate dimension: 700×800 mm

- Maximum cutting press closing force (adjustable): 20000 kg

- Cutting press punch-holder plate dimension: 700×800 mm

- Cutting press working plate dimension: 700×800 mm

- Turntable working stations dimension: 700×800 mm

- Output power of the generator: 20 kW

- Working frequency: 27.12 MHz ± 0.6%

- Feeding voltage: 400 V – 3Ph+G – 50 Hz (other voltages on request)

- Compressed air pressure: 0.6 Mpa

- High frequency welding press hydraulically operated

- High frequency generator incorporated in the structure of the press

- Cutting press hydraulically operated

- Turntable with 6 working stations and adjustable rotating speed

- Hydraulic power pack

- Liquid circulation refrigeration unit (on request)

- Photoelectric protection barrier in operator stations

- Control panel with PLC (remote service on request)

- Push-button panel with touch screen

GMA-D Model

- Product: blood filters

- Output: 800 pieces/hour

- Maximum port welding press closing force: 750 kg

- Maximum filter welding press closing force: 1600 kg

- Maximum tube welding press closing force: 1200 kg

- Press electrode-holder plate dimension: 450×550 mm

- Press working plate dimension: 450×550 mm

- Turntable working station dimension: 450×550 mm

- Output power of the port generator: 3 kW

- Output power of the filter generator: 12 kW

- Output power of the tube generator: 12 kW

- Working frequency: 27.12 MHz ± 0.6%

- Feeding voltage: 400 V – 3Ph+G – 50 Hz (other voltages on request)

- Compressed air pressure: 0.6 Mpa

- High frequency welding press pneumatically operated for ports

- High frequency generator incorporated in the structure of the press

- High frequency welding press pneumatically operated for filters

- High frequency welding press pneumatically operated for tubes and perimeter

- Turntable with 8 working stations and adjustable rotating speed

- Liquid circulation refrigeration unit

- Control panel with PLC (remote service on request)

- Push-button panel with touch screen

DRAINAGE & URINE BAGS

GMA-D 4 Stations Drainage Bags

- Product: PVC drainage bags of 3000 ml

- Output: 1500 pieces/hour

- Maximum press closing force: 2500 kg

- Press electrode-holder plate dimension: 700×800 mm

- Press working plate dimension: 700×800 mm

- Turntable working stations dimension: 700×800 mm

- Output power of the generator: 20 kW

- Working frequency: 27.12 MHz ± 0.6%

- Feeding voltage: 400 V – 3Ph+G – 50 Hz (other voltages on request)

- Compressed air pressure: 0.6 Mpa

- High frequency welding press pneumatically operated

- High frequency generator incorporated in the structure of the press

- Turntable with 4 working stations and adjustable rotating speed

- Liquid circulation refrigeration unit

- Automatic loader

- Automatic unloader

- Control panel with PLC (remote service on request)

- Push-button panel with touch screen

GMA-D 6 Stations Drainage Bags

- Product: PVC drainage bags of 3000 ml

- Output: 900 pieces/hour

- Maximum press closing force: 2500 kg

- Press electrode-holder plate dimension: 700×800 mm

- Press working plate dimension: 700×800 mm

- Turntable working stations dimension: 700×800 mm

- Output power of the generator: 15 kW

- Working frequency: 27.12 MHz ± 0.6%

- Feeding voltage: 400 V – 3Ph+G – 50 Hz (other voltages on request)

- Compressed air pressure: 0.6 Mpa

- High frequency welding press hydraulically operated

- High frequency generator incorporated in the structure of the press

- Turntable with 6 working stations and adjustable rotating speed

- Hydraulic power pack

- Liquid circulation refrigerating unit

- Automatic loader

- Control panel with PLC (remote service on request)

- Push-button panel with touch screen

GMA-D 4 Stations Urine bags

- Product: PVC drainage bags of 3000 ml

- Output: 900 pieces/hour

- Maximum press closing force: 2500 kg

- Press electrode-holder plate dimension: 700×800 mm

- Press working plate dimension: 700×800 mm

- Turntable working stations dimension: 700×800 mm

- Output power of the generator: 15 kW

- Working frequency: 27.12 MHz ± 0.6%

- Feeding voltage: 400 V – 3Ph+G – 50 Hz (other voltages on request)

- Compressed air pressure: 0.6 Mpa

- High frequency welding press hydraulically operated

- High frequency generator incorporated in the structure of the press

- Turntable with 6 working stations and adjustable rotating speed

- Hydraulic power pack

- Liquid circulation refrigerating unit

- Automatic loader

- Control panel with PLC (remote service on request)

- Push-button panel with touch screen

GMA-D 6 Stations Urine Bags

- Product: PVC drainage bags of 3000 ml

- Output: 900 pieces/hour

- Maximum press closing force: 2500 kg

- Press electrode-holder plate dimension: 700×800 mm

- Press working plate dimension: 700×800 mm

- Turntable working stations dimension: 700×800 mm

- Output power of the generator: 15 kW

- Working frequency: 27.12 MHz ± 0.6%

- Feeding voltage: 400 V – 3Ph+G – 50 Hz (other voltages on request)

- Compressed air pressure: 0.6 Mpa

- High frequency welding press hydraulically operated

- High frequency generator incorporated in the structure of the press

- Turntable with 6 working stations and adjustable rotating speed

- Hydraulic power pack

- Liquid circulation refrigerating unit

- Automatic loader

- Control panel with PLC (remote service on request)

- Push-button panel with touch screen

Enteral and Parenteral Alimentation Bags

We offer automatic, semi-automatic, and manual machines for the production of enteral and parenteral feeding bags of non-PVC and EVA film.

UNILINE Model

- Product: EVA medical bags for enteral and parenteral alimentation with three tubes, 1000 ml – 3000 ml

- Output: 800 pieces/hour (2000 ml bags)

- Maximum reel diameter: 400 mm

- Maximum reel width: 450 mm

- Maximum press closing force: 1600 kg

- Press upper plate dimension: 450×600 mm

- Press down plate dimension: 550×700 mm

- Indexing unit forward (minimum – maximum): 150 – 520 mm

- Output power of the generator: 15 kW

- Working frequency:12 MHz ± 0.6%

- Feeding voltage: 400 V – 3Ph+G – 50 Hz (other voltages on request)

- Compressed air pressure: 6 Mpa

- Reel-holder for tubular film

- Hot printing unit

- Tube unwinding, cutting and positioning

- High frequency welding press pneumatically operated

- High frequency generator incorporated in the structure of the press

- Index device by a mobile clamp operated by a brushless motor

- Automatic scrap removal unit

- Liquid circulation refrigeration unit

- Control panel with PLC (remote service on request)

- Push-button panel with touch screen

GMA-D + PDT Model

- Product: EVA medical bags for enteral alimentation, 2000 ml

- Output: custom

- Maximum welding press closing force (adjustable): 2500 kg

- Welding press electrode-holder plate dimension: 700×800 mm

- Welding press working plate dimension: 700×800 mm

- Maximum cutting press closing force (adjustable): 20000 kg

- Cutting press punch-holder plate dimension: 700×800 mm

- Cutting press working plate dimension: 700×800 mm

- Turntable working stations dimension: 700×800 mm

- Output power of the generator: 20 kW

- Working frequency: 27.12 MHz ± 0.6%

- Feeding voltage: 400 V – 3Ph+G – 50 Hz (other voltages on request)

- Compressed air pressure: 0.6 Mpa

- High frequency welding press hydraulically operated

- High frequency generator incorporated in the structure of the press

- Cutting press hydraulically operated

- Turntable with 6 working stations and adjustable rotating speed

- Hydraulic power pack

- Liquid circulation refrigeration unit (on request)

- Photoelectric protection barrier in operator stations

- Control panel with PLC (remote service on request)

- Push-button panel with touch screen

IV Bags

When you require reliable high-speed and flexible PVC or non-PVC IV bag manufacturing systems, we have the expertise and the partnership to help you get your product to market. ACIC’s customized solutions offer the flexibility to have the Form Fill Seal processes as one single system (FFS) or two individual systems (F + FS).

Our Experience Includes:

- Automatic or semi-automatic bag forming, filling, and sealing machines (as individual systems or a single machine)

- Single or multi-chamber bags

- PVC or non-PVC film

- Mono or multi-layer film

- Customized connection options (boat port, round port, or flexible tubes)

- Our machines can handle all filling volumes, from very small to very large filling volumes

- High-speed output rates to meet capacity demands

- Flexible, custom-designed systems based on client requirements

Forming Machines for IV Bags

We provide fully automatic machines suitable for IV bag making under strict pharmaceutical requirements.

The machine is composed of the following main parts: film unwinding station, film transfer station, tube reel magazine, tube feeding station, bag forming, and tube or port insertion station, hot foil printing station, and bag cutting station.

- Optimized design and structure to allow easy cleaning for all working surfaces due to the absence of dead zones and corners

- Low energy consumption

- Reduced start-up time

- Capability to handle different kinds of films

- Different bag sizes and customizable shapes

- Single or multi-chamber bag mold

- Productivity up to 1,700 bags / hour

- Simple orientation, quick change-overs, and low maintenance

- High production rates and line efficiency

- Compliant with 21 CFR part 11 FDA guideline

- User friendly touch screen operator interface (HMI)

- Customized layout in accordance to special end-user demands

- Tube ultrasonic sealing

- Peelable sealing of multi-chamber bags

- Insertion of different accessories such as, spike, injection port, stopper, or special connector

- Accessory sealing with hot air and other methods up on request

- Closure presence control and automatic rejection systems

- Remote assistance

- Printer and SCADA interface for production data recording and management

- Integration with convectional LAF or RABS

- Documentation packages for complete system validation

- Inline connection with RASR Series of bag filling machines

Automatic and Semi-Automatic Filling & Closing Machines for IV Bags

We provide semi-automatic and fully automatic machines for filling and closing of preformed bags of various capacities and materials (PVC, PE, PP, etc.).

The dosing unit is equipped with mass-flow meters that guarantee an accurate and stable filling process. Different filling devices can also be used depending on the product characteristics.

The machine can process bags of very small and very large scale filling outputs.

- Optimized design and structure to allow easy cleaning for all working surfaces due to the absence of dead zones and corners

- Rotary or linear configuration

- Single or multiple filling stations, depending on the bag volumes

- All product contacting parts are made of AISI 316L stainless steel with finishing ranging from 0.4 – 0.8 RA, or with FDA approved materials

- Basic closure station with ultrasonic sealing or caps insertion

- Cap presence control

- Pre-arrangements for future upgrade

- Rejection station in a single tray

- Simple orientation, quick change-overs, and low maintenance

- Compliant with 21 CFR part 11 FDA guideline

- User friendly touch screen operator interface (HMI)

- Customized layout in accordance to special end-user demands

- Automated loading/unloading systems with robot

- Vacuum before filling

- Insert gas flushing after filling

- Descaled and passivized filling circuit

- Statistical or 100% IPC

- CIP/SIP preparation

- Remote assistance

- Printer and SCADA interface for production data recording and management

- Integration with convectional LAF or RABS

- Documentation packages for complete system validation

- More than one closing station, depending on the type of bag to be processed

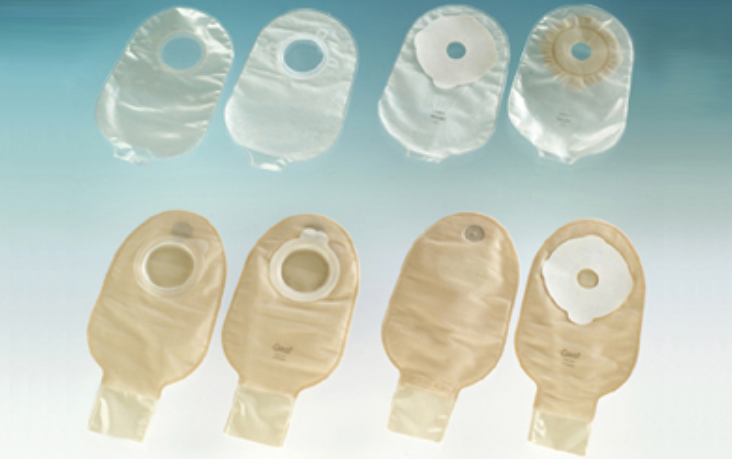

Ostomy Bags

We provide automatic lines for the production of ileostomy, colostomy and urostomy bags (closed and drainable bags) in EVA film and TNT film.

UNIOST Model

- Product: colostomy medical bags

- Output: 1100 pieces/hour

- Maximum reel diameter: 400 mm

- Maximum reel width: 345 mm

- Maximum press closing force: 1200 kg

- Press upper plate dimension: 350×350 mm

- Press down plate dimension: 350×350 mm

- Indexing unit forward: 350 mm

- Output power of the generator: 8 kW

- Working frequency:12 MHz ± 0.6%

- Feeding voltage: 400 V – 3Ph+G – 50 Hz (other voltages on request)

- Compressed air pressure:6 Mpa

- Ink-jet printing unit

- One-piece flange (injection) loading unit

- One-piece flange thermo-contact welding press pneumatically operated

- Two-piece flange (semi-finished) loading unit

- Two-piece flange thermocontact welding press pneumatically operated

- Lateral 3-position reel-holder with unwinder

- Charcoal filter loading unit

- Charcoal filter thermo-contact welding press pneumatically operated

- Indexing unit through two lateral chains operated by electric motor

- Automatic unloader with non-conforming unit identification

- Liquid circulation refrigeration unit

- Control panel with PLC (remote service on request)

- Push-button panel with touch screen

Plasma Bags

UNILINE Model

- Product: EVA medical bags with three tubes for plasma (1000 ml – 3000 ml)

- Output: 800 pieces/hour (2000 ml bags)

- Maximum reel diameter: 400 mm

- Maximum reel width: 450 mm

- Maximum press closing force: 1600 kg

- Press upper plate dimension: 450×600 mm

- Press down plate dimension: 550×700 mm

- Indexing unit forward (minimum – maximum): 150 – 520 mm

- Output power of the generator: 15 kW

- Working frequency: 27.12 MHz ± 0.6%

- Feeding voltage: 400 V – 3Ph+G – 50 Hz (other voltages on request)

- Compressed air pressure: 0.6 Mpa

- Reel-holder for tubular film

- Hot printing unit

- Tube unwinding, cutting and positioning

- High frequency welding press pneumatically operated

- High frequency generator incorporated in the structure of the press

- Index device by a mobile clamp operated by a brushless motor

- Automatic scrap removal unit

- Liquid circulation refrigerating unit

- Control panel with PLC (remote service on request)

- Push-button panel with touch screen

GMA-D + PDT Model

- Product: EVA medical bags for plasma (2000 ml)

- Output: according to welding times and operator skills

- Maximum welding press closing force (adjustable): 2500 kg

- Welding press electrode-holder plate dimension: 700×800 mm

- Welding press working plate dimension: 700×800 mm

- Maximum cutting press closing force (adjustable): 20000 kg

- Cutting press punch-holder plate dimension: 700×800 mm

- Cutting press working plate dimension: 700×800 mm

- Turntable working stations dimension: 700×800 mm

- Output power of the generator: 20 kW

- Working frequency: 27.12 MHz ± 0.6%

- Feeding voltage: 400 V – 3Ph+G – 50 Hz (other voltages on request)

- Compressed air pressure: 0.6 Mpa

- High frequency welding press hydraulically operated

- High frequency generator incorporated in the structure of the press

- Cutting press hydraulically operated

- Turntable with 6 working stations and adjustable rotating speed

- Hydraulic power pack

- Liquid circulation refrigerating unit (on request)

- Photoelectric protection barrier in operator stations

- Control panel with PLC (remote service on request)

- Push-button panel with touch screen